Leak Repair Clamps

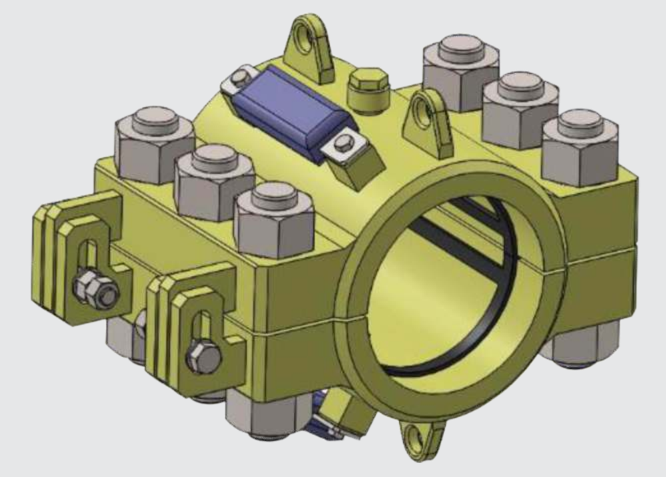

Leak Repair Clamps are extensively used for the quick, effective, and reliable repair of pipelines carrying oil, gas, water, steam, and various chemical fluids, across both high and low temperature applications. To begin with, these clamps are designed as split assemblies, in which two halves are securely bolted together to form a high-integrity pressure enclosure around the leaking or damaged section of the pipe. Furthermore, sealing is achieved through high-quality elastomer seals, which are carefully selected based on compatibility with the pipeline’s fluid type and operating temperature conditions. In addition to their sealing capability, Leak Repair Clamps offer extended functionality. For instance, operators can weld them post-installation to create a permanent, pressure-tight solution.

Moreover, in critical scenarios, they may be completely seal-welded while the pipeline remains in operation. As a result, these clamps ensure minimal operational disruption, while simultaneously delivering maximum efficiency, safety, and durability in demanding pipeline systems.

Features of Leak Repair Clamps

Leak Repair Clamps are fitted with a high-grade elastomeric seal, typically made from Buna-Nitrile or Viton. To begin with, in these applications, the sealing load is achieved through bolt tensioning of the clamp studs, following a split sleeve design. In addition, all clamps include an external pressure test facility, which allows operators to verify joint integrity prior to commissioning. Furthermore, for enhanced functionality, a twin seal configuration is also available, enabling inter-seal testing during installation.

Moreover, manufacturers can supply Leak Repair Clamps for both topside and subsea repair applications, thus offering flexibility across a wide range of environments. For more specific requirements, engineered solutions can incorporate a metal graphite composite seal, which comes standard in all Split Sleeve Clamp Mechanical Contractor products. Importantly, this graphite-based sealing provides a chemically resistant, high-temperature, and high-pressure solution. As a result, it ensures long-term performance without degradation, even in harsh or aggressive conditions.

Benefits of Leak Repair Clamps

Leak Repair Clamps work well for leaking pipes or wall thinning. They self-seal through the bolting of clamp studs. Standard clamps have a single seal. However, double seals are available on request.

Each clamp is hydro tested at 1.5 times its design pressure or as per client needs. They are commonly used for both subsea and topside repairs.

Wedge-shaped grooves prevent seal slippage during installation. The design follows ASME VIII standards. Prep angles can be added for welding when required.

Material Specification

| Pipe Sizes | 1″ & Above |

| Split Body Shell | SA / ASTM A 516 Gr. 70 ASTM A 106 GR A, B, C Seamless Pipe ASTM A516 Gr. 70 Steel Plate API 5L Gr B, X42, X46, X52, X56, X60, X65, X70 ASTM A36 ASTM A572 Gr42, Gr50, Gr55, Gr60, Gr65 ASTM A516 Gr55, Gr60, Gr65, Gr70 ASTM A537 Class 1, Class 2, Class 3 EN 10025 ASTM A216 WCC ASTM A352 LCC ASTM A216 WCB Any other as per client requirement. |

| Body Flange (Stiffner) | ASTM A350 LF2 / ASME || SA350 LF2 ASTM A105 / ASME || SA105 Any other as per client requirement. |

| Stud & Nut | ASTM A 193 Gr. B7, with A194 Gr 2H or as per client requirement Nuts. ASTM A 194 Gr2.2H, 2HM, 4, 7, 7M, 8, 8M ASTM A307 Gr A, B, C ASTM A320 Gr L7, L43 ASTM A325 Gr Type 1, Type 2, Type 3 Any other as per client requirement. Coating: Yellow Epoxy Polyamide, Standard or Marine Epoxy Galvanized, PTFE, Xylan Coated or any other as per client requirement |

| Seals / Gaskets | NBR temperature range is from -20°C to +80°C Viton temperature range is from -20°C to +200°C Silicone, Kevlar, Hycar HNBR temperature range is from -20°C to +150°C Any other as per client requirement |

| Vent Plug | SA / ASTM A 105 |

| Lifting Plug | SA / ASTM A 516 Gr. 70 |

| Sacrifical Anode | Zinc Alloy Any other as per client requirement. |

| Hinges Assembly | SA / ASTM A516 Gr. 70 SA / ASTM A-325 ASTM A106 Gr A, B, C, Seamless Pipes ASTM A572 Gr42, Gr50, Gr55, Gr60, Gr65 ASTM A516 Gr55, Gr60, Gr65 ASTM A36 ASTM A537 Class 1, Class 2, Class 3 EN 10025 – S235, S275, S355, S540 ASTM A 193 Gr. B7, with A194 Gr 2H Nuts. ASTM A 194 Gr2.2H, 2HM, 4, 7, 7M, 8, 8M ASTM A307 Gr A, B, C ASTM A320 Gr L7, L43 ASTM A325 Gr Type 1,Type 2,Type 3 Any other as per client requirement. |

| Design Code | ASME SEC VIII DIV . 1 API 6H ANSI B31.3 ANSI B31.4 ANSI B31.8 |

| Design standards | API SPEC 6H, Specification on End Closures, Connectors and Swivels API SPEC 5L, Specification for Line Pipe ASME Pressure Vessel Code, Section VIII ASME/ANSI B18.2.1, Square and Hex Bolts and Screw Inch Series |

| Design Pressure | 300#, 400#, 600#, 900#, 1500#, 2500# Any other as per client requirement. |

| Hydrotest Pressure | 1.3 X Design Pressure 1.5 X Design Pressure Any other as per client requirement. |

| Design Temperature | 0 to 212°F Any other as per client requirement. |

| Design Temperature | Yellow Epoxy Polyamide, Standard or Marine Epoxy, Galvanized, PTFE, Xylan Coated Any other as per client requirement. |

Applicable International Standards

The design, engineering, and supply of the fire tubes (two off) shall conform, wherever applicable, and unless otherwise specified and agreed, to the appropriate API, ASTM, ANSI, ASME, or equivalent standards and codes. In addition, they shall comply with internationally accepted standards and practices. Moreover, all standards and codes followed for the design shall be of the latest version or edition, ensuring up-to-date compliance and reliability.

API RP 1160 | Managing System Integrity of Hydrocarbon Liquid Pipelines |

ASME B 31.4 | Pipeline Transportation System for Liquids |

ASME Section IX | Specification for Welding and Brazing Qualifications |

ASME Section V | Non Destructive Examination |

ASME Section II Part C | Specification for Welding Rods, Electrodes and Filler Materials |

ASME Section VIII, Div 1 | Rules for Construction of Pressure vessels |

ASTM E 94 | Standard guide for Radiographic examinations |

ASTM E709 | Standard guide for Magnetic Particle examination |

ASTM E1003 | Standard test method for Hydrostatic Leak testing |

Testing & Certifications

- Non-destructive testing (NDT)

- 100% magnetic particle inspection (MPI) for stiffener to shell weld (fillet)

- 100% ultrasonic testing of vent plug welds

- 100% MPI fo hinge welds

- Hydro Test as per ASME Secion VIII Div. 1 clause UG-99 Dimensional & Visual

- Hardness

- Load Testing of Hook & Hinge Painting Inspection

- Any other as per client requirement.

Weldable Split Sleeves

Additionally, all clamps can be fully prepared for welding after installation, and the welding procedure is available upon request. To further enhance safety, heat insulators placed parallel to the seals protect them from heat during the welding of the sleeves to the pipe. Moreover, clamps with longer lengths are available upon request, offering greater flexibility for varied pipeline repair needs.

Contact for Pipe repaire Leak.

For more details on the products contact us.

Half Pipe Sleeve, Half Repair Pipe Sleeve, Pre-Stressed Metallic Sleeve.