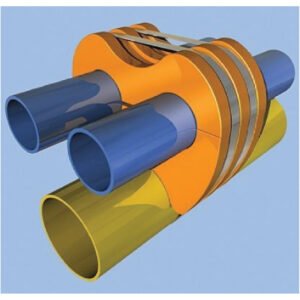

Piggy Back Clamp

In today’s complex industrial environments, the ability to safely and efficiently secure secondary lines—such as cables, conduits, or small-diameter pipes—onto existing pipeline infrastructure is critical. Traditional methods often involve invasive techniques like welding or drilling, which can compromise the host pipe’s structural integrity, require significant downtime, or inflate installation costs.

What sets Half Pipe Sleeve apart is not just the product—it’s the precision with which it’s built, the standards it complies with, and the peace of mind it offers across a broad spectrum of applications. Whether you’re dealing with saltwater corrosion, fluctuating temperatures, or spatial limitations, these clamps adapt quickly and perform consistently.

Piggy Back Clamp Applications

Designed for industries that demand strength, speed, and reliability, these clamps enable the non-disruptive mounting of auxiliary lines onto main pipelines or structural frameworks. From subsea oil rigs and petrochemical plants to high-rise HVAC systems and tunnel utilities, this solution is engineered to deliver exceptional grip, vibration resistance, and corrosion protection in even the most extreme environments.

Piggyback Clamp Solutions are mechanical clamping systems used to attach secondary pipelines or cables to an existing main pipeline. This solution facilitates efficient routing of additional lines without altering or compromising the integrity of the host structure.

Key Features & Benefits

- Non-Invasive Mounting: No welding or drilling required.

- Corrosion & UV Resistance: Ideal for marine and offshore environments.

- Precision Stability: Prevents movement and abrasion of secondary lines.

- Tool-Assisted, Fast Installation: Saves time and labor.

- Highly Customizable: Multiple designs to fit varied applications.

- Resilient Construction: Withstands stress, vibration, and temperature fluctuations.

Technical Composition & Specifications

| Component | Material/Feature |

| Main Pipe Size Range | 2″ to 48″ |

| Secondary Line Size | 0.5″ to 6″ |

| Clamp Body | UV-resistant polymer, high-strength polyurethane, HDPE, or thermoplastic elastomers |

| Fasteners & Straps | 316L stainless steel, Inconel 625, or polymer-based banding |

| Elastomer Inserts | Optional vibration-damping materials |

| Coating Options | Custom chemical-resistant or marine-grade coatings |

| Design Type Variants | Saddle-type, split-block, strap-based, spring-loaded, segmented, bolt-down types |

Applications Across Industries

- Oil & Gas / Marine: Attaching umbilicals, chemical lines, and control cables.

- Construction: Securing pipelines along bridges, tunnels, and beams.

- HVAC / Plumbing: Organizing water or refrigerant lines.

- Telecom / Electrical: Bundling fiber optic and power conduits.

- Industrial Equipment: Routing hydraulic lines in machinery.

Clamp Variants Offered

| Type | Description |

| Single Strap Clamp | Light-duty, wraps around host and secondary pipe with one strap |

| Double Strap Clamp | Heavy-duty applications, added stability with dual straps |

| Spring-Loaded Clamp | Maintains tension for high-vibration scenarios |

| Adjustable Clamp | Fits varied pipe sizes; useful for multi-line environments |

| Split-Block Clamp | Two-piece design with full circumferential grip |

| Saddle-Type Clamp | Space-saving, contoured for tight installations |

| Bolt-Down Clamp | Bolted directly to host pipe; ensures high mechanical strength |

| Segmented Clamp | Customizable for rigs and variable pipe geometries |

Design & Construction

| Design Feature | Details |

| Load Distribution | Engineered to reduce stress on host structures |

| Compact Form Factor | Optimized for tight installations and confined access zones |

| Anti-Vibration Inserts | Optional for added motion control and longevity |

| Tool Compatibility | Can be installed using basic mechanical tools |

| Custom Shapes & Grooves | Tailored to grip specific pipe/cable diameters securely |

Installation Guidelines for Piggy Back Clamp

Steps to Follow:

- Identify and prep the mounting area.

- Place clamp saddle around the host pipe.

- Fit the secondary line into the designated groove.

- Secure using fasteners or bolts to recommended torque.

- Conduct a final check for alignment and stability.

Best Practices:

- Maintain uniform spacing.

- Use anti-seize lubricant on bolts.

- Match materials to environment (marine, underground, industrial).

- Schedule regular inspections post-installation.

Compliance & Certifications

| Standard | Description |

| ISO 9001:2015 | International Quality Management System |

| ISO 14001:2015 | Environmental Management Compliance |

| ISO 45001:2018 | Occupational Health & Safety |

| PED Certified | Pressure Equipment Directive approval |

| API Standards | Industry-specific compliance for oil & gas environments |

| CE Marked | Meets EU health, safety, and environmental protection standards |

Why Choose Half Pipe Sleeve’s Piggyback Clamp Solution?

Half Pipe Sleeve delivers years of expertise, certified engineering, and robust infrastructure-grade products. Our Piggyback Clamp Solutions offer a flexible, rugged, and low-maintenance alternative to traditional pipe support methods—perfect for rapid deployment in high-stakes environments.

No welding. No downtime. Just seamless performance.