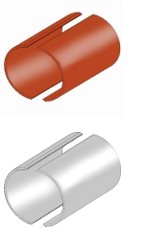

Half Pipe Sleeves

Half Pipe Sleeve Manufacturer

As a leading Half Pipe Sleeve Manufacturer, we design and fabricate a comprehensive range of pipeline repair products, including Half Pipe Sleeves, Half Sole Repair Sleeves, Pre-Stressed Metallic Sleeves, Leak Defect Repair Sleeves, and Split Sleeves.

At Pipeline Products Inc., we engineer solutions that help you avoid costly shutdowns. Our designs enable you to carry out repairs without stopping the carrier line, allowing your existing pipelines to remain operational without any loss of thru-put. We offer a complete range of sizes, ASTM-grade steel plates—available in both structural and pressure vessel quality—various wall thicknesses, and longitudinal edge options tailored to your specific requirements.

We custom-fabricate our Half Sole Repair Sleeves (also known as split casing or half wrap) to ensure a precise fit and reliable performance. You can choose from four material types: two pressure-rated steels for repairing leaking or non-leaking defects, and two structural-grade steels for reinforcing weakened areas of the pipeline.

Contact us today to get a dependable, custom-made repair solution that keeps your operations running smoothly.

Reliable Solutions by a Trusted Half Pipe Sleeve Manufacturer.

As a leading Half Pipe Sleeve Manufacturer, we engineer and deliver Steel Repair Sleeves that provide superior performance in pipeline repair and reinforcement. These sleeves effectively resolve a broad range of pipeline challenges, including internal and external corrosion, gouges, dents, grooves, arc burns, cracks, defective girth welds, laminations, and leaks. Moreover, we design each solution with performance, reliability, and field adaptability in mind.

We manufacture our pressure-containing sleeves with wall thickness equal to—or greater than—the requirement for the maximum allowable operating pressure, or to match the full strength of the pipe being repaired. As a result, our sleeves ensure long-lasting durability and field-ready performance under demanding conditions. Additionally, we craft every Steel Repair Sleeve using steel with a carbon equivalent not exceeding 0.45%, ensuring full compliance with stringent quality standards.

Features of High-Quality Half Pipe Sleeve

As a trusted Half Pipe Sleeve Manufacturer, we provide precision-engineered half-sole segments with pre-crimped back-up strips, ensuring easy installation and structural reliability. Our sleeves are also versatile, serving as pads or cradles for above-ground piping, drain tile supports, and custom patches. We offer special segment lengths in 90° and 180° arcs, ranging from 6 inches to 10 feet, upon request.

All our half pipe sleeves come with standard bevels, square-cut ends, and certified material documentation. While our Standard Girth Weld Steel Repair Sleeves are supplied without a back-up strip, this feature can be included upon special request. As a dedicated Half Pipe Sleeve Manufacturer, we focus on delivering solutions that uphold pipeline integrity without requiring operational shutdowns.

MATERIAL

Material used are structural quality carbon steel or pressure vessel quality carbon steel plates, which are to ASTM specifications, and in the following grades:

API 5L Gr B, X42, X46, X52, X56, X 60, X 65, X70 – PSL 1 – PSL2 (minimum yield 42000 / 52000 / 60000 / 65000 / 70000)

ASTM A36 (structural; minimum yield 36,000 psi) ASTM A572 GR42, GR50, GR55, GR60, GR65 (structural; minimum yield 29,000 psi) ASTM A516 GR55, GR60, GR65, GR70 (pressure vessel; minimum yield 38,000 psi) ASTM A537 Class I, Class 2, Class 3 (pressure vessel; minimum yield 50,000 psi) EN 10025 – S235, S275, S355, S450

The chemical composition does not exceed the percentages specified for the ASTM material ordered. Repair sleeves are fabricated from plate with low carbon equivalency for good weld ability.

The maximum allowable carbon equivalency (CE) quality carbon steel plates will be based on the heat analysis. The maximum allowable carbon equivalency (CE) pressure vessel quality carbon steel plates will be based on the heat analysis, in most cases.

Note : The sleeve can be manufactured in any grade as per the application & client requirements.

MANUFACTURING

Leading Half Pipe Sleeve Manufacturer for Precision Pipeline Repair.

At Pipeline Products Inc, we are a trusted Half Pipe Sleeve Manufacturer, delivering high-quality sleeves formed by rolling, step braking, or die forming—without heat treatment, ensuring material integrity.

Product Specifications

Typical Applications:

Permanent repair of splits, holes, punctures, corroded areas, inferior welds, and gouges.

Our Half Pipe Sleeves are precisely fabricated for a secure fit and long-term durability in high-performance pipeline systems.

TEST METHODS

a) Chemical Analysis Test

The method for material chemical analysis is done as per ASTM A751. This is as per API 5L standard section 9.10 subsection one.

b) Tensile Test

Our test Method for material tensile test is done as per ASTM A370. This is as per API 5L standard section 9.10 subsection two

c) Equipment Calibration

This is done within 15 months according to ASTM E4 under API 5L standard section 9.10.2.2

d) Guided Bend Tests

Shall be performed to conform to API 5L standard section 9.10.3 and within subsequent reference

e) Charpy Tests

Shall be performed in accordance with ASTM A370 as per API standard section 9.10.4

f) Other tests

Invalidation of Tests (as Per API 5L 9.11.1/2) , Retests (i) Recheck Analysis API 5L 9.12.1 (ii) Recheck Analysis API 912.2 , Flattening Tests ( API 5L 9.12.3) , Bend Retest (API 5L 9.12.4) , Guided Bend Retest ( API 5L 9.12.5) , Charpy Rest ( API 5L 9.12.6) , Reprocessing ( API 5L 9.13)

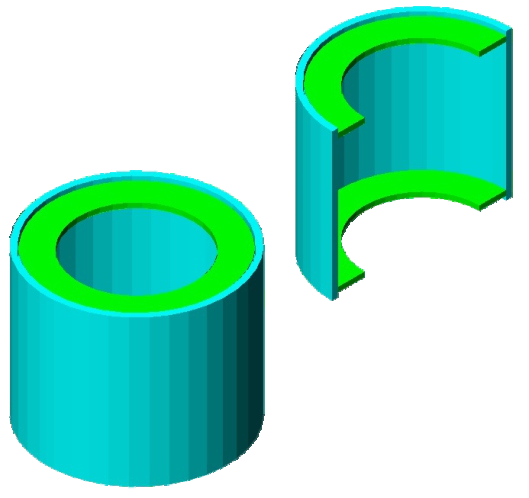

CARBON STEEL & STAINLESS STEEL WELD ON REPAIR SLEEVE

We design and manufacture Carbon Steel Weld On Repair Sleeves and Stainless Steel Weld On Repair Sleeves to repair and reinforce in-service steel pipelines without requiring shutdown or service interruption. These sleeves effectively address a variety of pipeline issues, including external or internal corrosion, dents, gouges, inferior welds, defective pipe material, and other structural weaknesses. As a result, operators can rely on our sleeves for efficient and non-disruptive repair solutions.

We offer these sleeves as either full-body repair sleeves or partial repair sleeves, depending on your specific application needs. Additionally, we supply each fitting standard beveled for welding, with square-cut sleeve ends and optional welding backup strips to support a smooth and secure installation process. Moreover, we provide both pressure-grade and structural-grade materials in carbon steel and stainless steel to suit a wide range of service conditions.

Our Weld On Repair Sleeves offer a range of practical features. We ensure immediate availability, and we custom-build each sleeve to match exact pipe diameters for a precise fit. Furthermore, we offer various material grades and wall thicknesses to meet specific application codes and requirements. These sleeves not only restore the host pipe to its original service capability, but also meet future performance expectations. To extend service life, we also apply protective coatings for corrosion resistance.

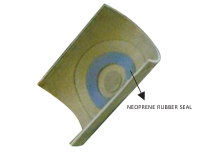

PRE-STRESSED METALLIC SLEEVE

We manufacture pre-stressed sleeves as full-encirclement split types, using a precise production process that minimizes the occurrence of mill defects. To ensure proper welding during assembly, we bevel the axial edges of each sleeve to create a 60° weld angle for the horizontal butt joint. Additionally, we machine a recess on the inner side of each half sleeve to accommodate a 3 mm thick by 18 mm wide backing strip along the horizontal joint. We fabricate these backing strips from the same material as the sleeves and supply them as part of the assembly, ensuring material compatibility and structural integrity.

Furthermore, we pre-fabricate the circumferential edges of the sleeves to form a 90° lap joint with the pipe, which enhances strength and stability. We also design and construct the internal diameter of each sleeve to fit snugly on the pipe, avoiding any gap between the sleeve’s inner surface and the pipe’s outer surface. This precise fit enhances sealing and overall performance.

During assembly and before welding, we maintain a maximum root gap of 3.0 mm on both horizontal joints and allow a 1.5 mm root face on both edges for proper welding geometry. In addition, we ensure both the horizontal and circumferential edges feature a smooth finish to facilitate clean, high-quality welds.

LEAK DEFECT REPAIR SLEEVE

Lightweight for easy handling and installation. Eliminates costly downtime. Minimizes repair costs. Complies with CSA Z183 and ANSI B31.4 Standards.

ENCAPSULTAING SLEEVE

RUPTURE SLEEVE – ENCAPSULATING SLEEVEIt is a Pipe Repair TYPE B Sleeve used to enclose / encapsulate a CLAMP: TEMPORARY LEAK REPAIR CLAMP – Rupture Clamp or any other leak joint over the main Pipeline. It encloses the additional material like Clamp or Flange over the Pipe and forms a Full Encirclement Sleeve joint To give a full strength to the defected portion of the pipeline with the help of welding.

GIRTH WELD SLEEVE

You can use Steel Repair Sleeves to fix internal and external corrosion, gouges, dents, grooves, arc burns, cracks, defective girth welds, laminations, and leaks. These sleeves handle high pressure, as we manufacture them with wall thickness equal to—or greater than—what’s required for the maximum allowable operating pressure or the full strength of the pipe.

We certify all Steel Repair Sleeve materials, and the carbon equivalent (long formula) does not exceed 0.45 percent. Each half-sole segment includes one pre-crimped back-up strip for secure installation.

Additionally, you can use Steel Repair Sleeves as pads or cradles for above-ground piping. They also support drain tiles and work well as patches. We offer patch segments in 90° and 180° arcs, with lengths from 6 inches to 10 feet, available upon request.

Each sleeve features standard longitudinal bevels, square-cut ends, and material certifications. While standard sleeves include bevels and a back-up strip, we do not include back-up strips with girth weld sleeves.

We follow ASTM specifications to produce girth weld sleeves using high-quality carbon steel plates. Depending on the application, we use either structural quality or pressure vessel quality carbon steel. Common grades include:

- ASTM A572 GR50

- ASTM A572 GR65

- ASTM A516 GR70

- ASTM A537 CL1

Moreover, we can custom-manufacture sleeves in any grade to meet your project’s specific needs

Contact for Pipe repaire Leak.

For more details on the products contact us.

Half Pipe Sleeve, Half Repair Pipe Sleeve, Pre-Stressed Metallic Sleeve.