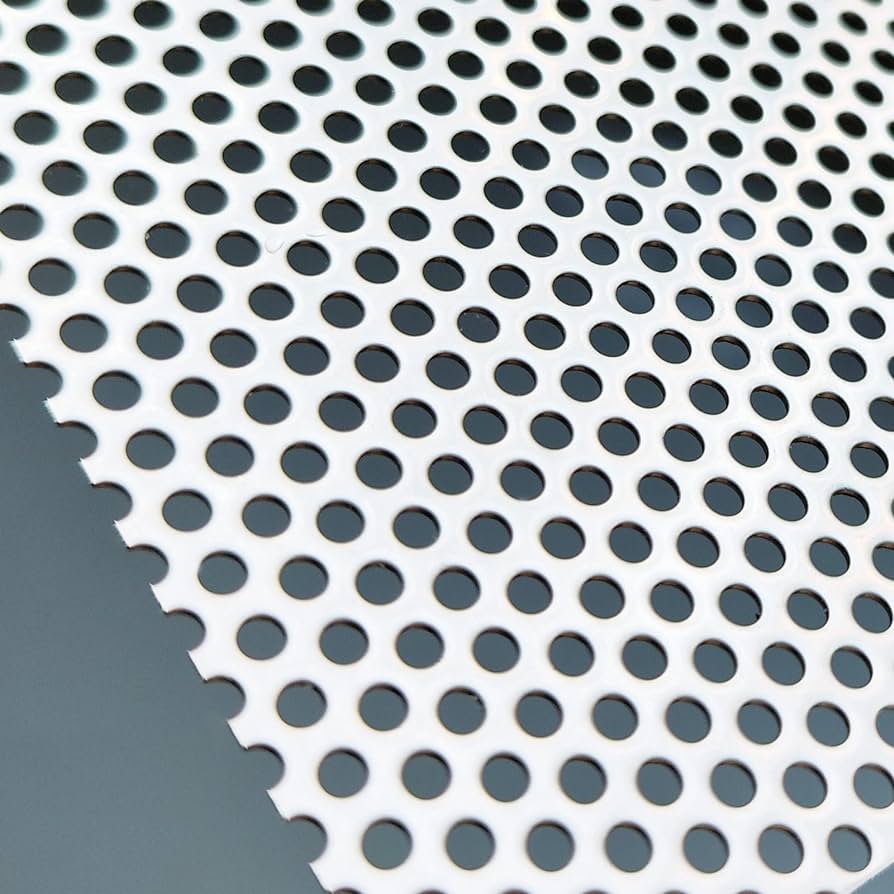

Plate Perforation

Plate Perforation plays a vital role in expanding the versatility of stainless steel sheets when it comes to usage. Specifically, perforated stainless steel sheet 4×8 is widely used in architecture and design for both structural and decorative purposes. As a result, it serves as a reliable and aesthetically appealing option for projects requiring strength, corrosion resistance, and visual appeal.

The Perforated Sheet is a low-carbon sheet alloyed with at least 10% chromium by weight. Thanks to its unique chemical composition—particularly the chromium content—a thin, invisible, and highly corrosion-resistant chrome oxide film forms on the surface. Moreover, this protective film has the remarkable ability to self-heal in the event of mechanical or chemical damage, thereby enhancing the material’s durability and lifespan.

Plate Perforation Sheet Specification

Perforated Sheet Specification – (FERROUS) | |

Chart : | · ASTM A240 / ASME SA240 |

Dimension List : | · ASTM, ASME, API, |

Grade : | · HRP, G60, G90 (CR Steel hot dip Zinc coated) etc. · SS A480 / A480M-18, · Typical Monel has 68% nickel and 29% copper. · GALVANIZED STEEL ASTM A283 Grade, A36, S235, S275, S355, |

Sizes (MM) : | · 1000 X 2000, 1219 X 2438, 1250 X 2500, 1500 X 3000; |

Width (MM) : | · 1000 TO 2000 & Customized sizes available. |

Thickness (MM) : | · 0.3 to 5.0, |

Length (MM) : | · 1000 TO 6000; |

Surface Finish :

| Surface finishes are provided by ASTM A480 and EN 10088. 2B, 2D, BA, No. 1, No. 4, No. 8, 8K, BA (Bright Annealed)-Mirror Finish, HR (Hot Rolled), CR (Cold Rolled), Satin (met with Plastic coated). |

Hardness : | · Soft, Hard, Half Hard, Quarter Hard, Spring Hard, etc. |

Perforation Hole Size : | · Ranging from 32 holes / in² to 320 holes / in² (5 holes/cm² to 50 holes/cm²). |

Perforated Sheet Specification – (NON FERROUS) | |

Grade : | · Copper grade – T1,T2, C11000, C12200, ASTM B152, C4621, etc. (1/16 hard,1/8 hard,3/8 hard,1/4 hard, etc.) · Naval Brass Plate, Alloy 260, Alloy 272, Alloy 330, Alloy 353, Alloy 360, Alloy 385, Alloy 464, Alloy C48200, C48500, |

Machines used to manufacture Perforated Plate | |

· Trumpf Tru Punch 5000 | · Amada EMK 3610NT |

Equipment List : | |

To produce accurate quality parts, our facility consists of modern press brakes and shears and roll forming equipment. · Perforating Presses · CNC Punches · Brakes · Bolt Hole Punches · Sheet Levelers · Roll Formers · MIG, TIG, STICK Welding Equipment Shears | |

Perforated Plate Industries wise Uses : | |

· Automobiles, · Audio equipment, · Drainage, · Food Processing, · Food Service Equipment, · Hospital & Health care, | · Appliances, · Computers, · Light Diffusion, · Food Processing, · Acoustical Dampening, · Oil Filtration, · Hydraulic Filtration, |

Perforated Products Applicability: |

Plate Perforation sheets are useful in many situations, such as reducing noise and weight, controlling airflow, filtering, or adding aesthetic appeal. Additionally, perforated sheets are ideal for sorting, screening, facades, ceilings, lights, shelves, shielding, staircases, and more due to their unique properties. Moreover, the stainless steel micro perforated sheet supports a wide range of applications across industries. These include agriculture, aerospace, lighting, security, air conditioning, sugar processing, and several others. As a result, their versatility makes them a practical and high-performance choice for diverse industrial needs. |

Perforated Plate Benefits : |

Perforated materials come with several key advantages that enhance their appeal in various industries. To start with, they help in lowering overall costs without compromising on performance. Furthermore, their malleability and flexibility allow easy shaping and adaptation across a wide range of applications. In addition, these materials offer improved strength while remaining lightweight and durable. This makes them ideal for both simple and complex projects, adding to their versatility. Not only that, perforated materials also have a low environmental impact, making them a sustainable choice. Moreover, in environments with electrical components and appliances, perforated shielding provides effective radiation containment. It can attenuate up to 99% of EMI and RFI radiation, offering a shielding effectiveness of 40 decibels, thus ensuring safety and performance. |

Perforated Plate Purpose : |

Perforated materials offer several practical advantages across applications. To begin with, they help in significant weight reduction, making structures lighter and more efficient. Additionally, the perforation pattern makes the material easier to tear or bend, which can be beneficial in manufacturing or assembly processes. Moreover, the openings allow for the controlled passage of light, sound, air, liquids, and gases. Depending on the design, these materials can either absorb or reflect sound, support ventilation, or manage fluid flow, thereby enhancing both function and efficiency. |

Perforated Plate Products : |

Perforated metal finds applications in a wide range of industries due to its strength, functionality, and visual appeal. For instance, it is commonly used in filtration and exhaust systems, as well as ventilation filters for HVAC systems and air conditioning panels, where airflow control is critical. In architectural design, it enhances building facades, suspended ceilings, and staircases, offering both aesthetic value and functionality. Additionally, its modern look makes it ideal for spaces where transparency is needed without obstructing the view. In public infrastructure, perforated sheets are used in outdoor furniture like benches and picnic tables, as well as garbage cans and ladder rungs, thanks to their durability and lightweight nature. Moreover, industries rely on them for material handling equipment, steel decking, and grain dryers. In the food and hospitality sector, they are ideal for kitchen equipment, appliances, food service equipment, and stainless steel sinks. Finally, they are widely used in speaker grills and light fixtures, where design and function go hand in hand. |

Perforated Sheet Specification

Specifications Chart: ASTM A240 / ASME SA240

Dimensions List: ASTM, ASME, and API

Sizes Chart in MM : 1000mm*2000mm,1250mm*2500mm,1219mm*2438mm,1500mm*3000mm.

Width in MM: 1000mm To 2000mm or customized

Thickness Chart in MM : 0.3mm – 15mm

Length in MM : 1000mm to 6000mm

Surface Finishes : 2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, Hot rolled plate (HR), Cold rolled sheet (CR), SATIN (Met with Plastic Coated) etc

Hardness : Soft, Hard, Half Hard, Quarter Hard, Spring Hard etc.

Contact for Pipe repaire Leak.

For more details on the products contact us.

Half Pipe Sleeve, Half Repair Pipe Sleeve, Pre-Stressed Metallic Sleeve.