What are Dish ends ?

Dished ends are the end caps welded to the main body of a pressure vessel. They are produced using a variety of production methods depending on the type of dished end required which will also need to reflect the characteristics of the end product.

How are dished ends made?

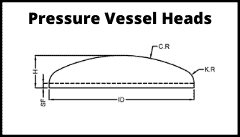

Pressure Vessel Heads

It is major Part of Pressure

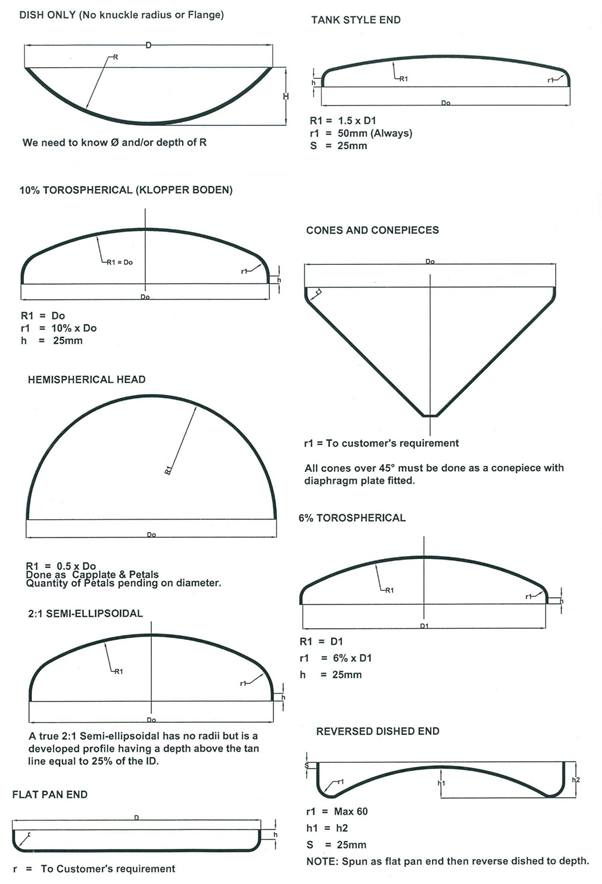

Types of Pressure Vessels Heads:

There are four basic types of pressure vessels heads or Dish ends is most widely used in fabrication of Pressure Vessels.

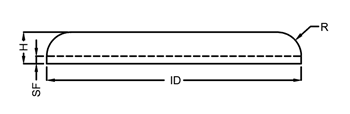

Flat Heads :

It is the simplest form of the pressure vessels heads but it has less usefulness in pressure vessels heads. So it is not preferred as much as of others because it has less pressure withstanding capacity than the other types of heads due to lower radial section is available for pressure distribution. So maximum exposure is comes on flat section so it is not economical.

Commonly Used terms in the Flat Head is Flat Head Inside Diameter (ID), Knuckle Radius (R), Dish End Total Height (H) and Straight Face (SF). Flat Heads General Drawing Representation is shown in above Drawing.

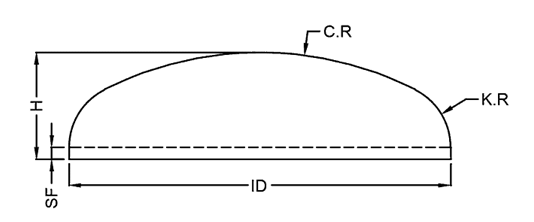

Ellipsoidal Heads :

It is a most widely used Pressure Vessel Heads. It has wider Radial section is available for pressure distribution.it withstand maximum pressure as compared to other heads. So it is most preferred pressure vessels heads. for same design condition, Dish end Thickness of ellipsoidal heads is approximately equals to shell thickness so it is most economical heads. Generally most used Ellipsoidal Heads Configuration is as per 2:1 Ellipsoidal Section.

Commonly Used Terms in 2:1 Ellipsoidal Heads is Inside Diameter (ID), Crown Radius (C.R), Knuckle Radius (K.R), Dish End Total Height (H) and Straight Face (SF). 2:1 Ellipsoidal Head General Drawing Representation is shown in above Drawing. Ellipsoidal Heads required more time of forming as compared to Flat Heads and Torispherical Heads. It is Most Economical Pressure Vessels Heads.

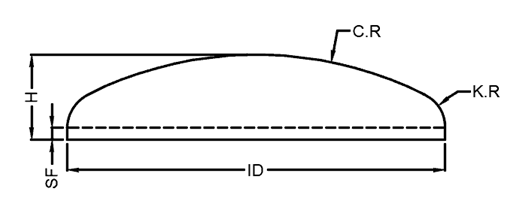

Torispherical Heads or Flange and Dished Heads :

It is also most widely used heads. It also has more radial section for pressure distribution so it also withstand maximum pressure but lower than ellipsoidal Heads. So that it is less economical than ellipsoidal heads but it also widely use due to lower time required for forming than the ellipsoidal heads.

So that for same design condition, Torispherical Heads Thickness is nearly 1.77 times the Shell Thickness for same Design Pressure and Temperature.

Commonly Used Terms in Torispherical Heads is Inside Diameter (ID), Crown Radius (C.R), Knuckle Radius (K.R), Dish End Total Height (H) and Straight Face (SF). Torispherical Head General Drawing Representation is shown in above Drawing.

It required less time of forming that ellipsoidal heads so it also more preferred heads due to simplicity of this heads. This Heads is also Called as Flange and Dished Heads.

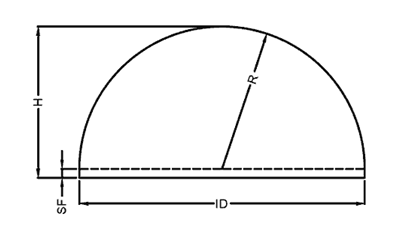

Hemispherical Heads:

This Head or Dish end is also used in pressure vessels fabrication. It has Maximum Radial Section is available than the other types of heads. Due to this it has maximum pressure distribution area is available.So that, for Same Design Condition Hemi Heads Thickness is approximately half of the shell Thickness for same pressure and Temperature.

So it is most economical Heads than the other types of Heads but it required maximum time of forming.

Commonly used terms in Hemi Heads is Inside Diameter (ID), Crown Radius (R), Dish end Total Height (H) and Straight Face (SF). Choice of Dish Ends is Depends upon Design Conditions and Their Applicability of Pressure Vessels Heads.

This are the four Basic Types of Dish ends are used in Pressure Vessels Fabrication. Most of the Dish end terms are calculated by using standard relationships with their inside diameter. On the Part of fabrication Point of View We have to Calculate various terms. This terms includes Dish End Terms, Blank Diameter, Weight, Surface Area, Volume Calculations are required in fabrication of Dish Ends.

Dish Ends can be supplied and manufactured in following Grades

| Grades | Material |

| API 5L | GRADE GR B, X42, GRADE X46 , GRADE X52, GRADE X56, GRADE X 60, GRADE X 65, GRADE X70 – PSL 1 – PSL2 (minimum yield 245000 / 52000 / 60000 / 65000 / 70000) |

| ASTM A36 | (structural; minimum yield 36,000 psi) |

| ASTM A572 | GRADE 42, GRADE 50, GRADE 55, GRADE 60, GRADE 65 (structural; minimum yield 29,000 psi) |

| ASTM A516 | GRADE 55, GRADE 60, GRADE 65, GRADE 70 (pressure vessel; minimum yield 38,000 psi) |

| ASTM A537 | Class I, Class 2, Class 3 (pressure vessel; minimum yield 50,000 psi) |

| EN 10025 |

GRADE S235, GRADE S235JR, Grade S235 J2,S235JRG1, GRADE S235JRG2, GRADE S235JO , GRADE S235J2G3, Grade S235 K2, GRADE S275, GRADE S275JR, GRADE S275JO , Grade S275 J2, GRADE S275J2G3, GRADE S275J2G4, GRADE S355, GRADE S355JR , GRADE S355JO, GRADE S355J2G3 , GRADE S355J2G4 , GRADE S355K2G3, GRADE S355K2G4, S355J2, S355K2, GRADE S450, Grade S450J0, GRADE S185, Grade S234J2G4, E 295 – E355 – E360, Grade S420 JR, Grade S420 JO,Grade S420 J2, Grade S690 JR, Grade S690 JO, Grade S690 J2, Grade S890 JR, Grade S890 JO ,Grade S890 J2, Grade S460JR, Grade S460J0, Grade S460J2, Grade S460K2, Grade S500J0, |

| ASTM A515 | GRADE 60, GRADE 65, GRADE 70 |

| EN 10028 |

GRADE P355NL1, GRADE P355NL2, GRADE P275NH, GRADE P460NL1, GRADE P460NL2, GRADE P460NH, GRADE P355NL1, GRADE P355NL2,GRADE P355NH, GRADE P235GH, GRADE P265GH, GRADE P295GH, GRADE P355GH, GRADE P235GH, GRADE P265GH, GRADE P295GH, GRADE P355GH,GRADE 360, GRADE 400, GRADE 430, P235GH, P265GH, P295GH, P355GH, 16Mo3, 18MnMo4-5, 20MnMoNi4-5, 15NiCuMoNb5-6-4, 13CrMo4-5, 13CrMoSi5-5, 10CrMo9-10, 12CrMo9-10, X12CrMo5, 13CrMoV9-10, 12CrMoV12-10, X10CrMoVNb9-1 |

| ASTM A238 | GRADE A, GRADE B, GRADE C, GRADE D |

| ASTM A285 | GRADE A, GRADE B, GRADE C |

| API 2H | GRADE 42, GRADE 50 |

| API 2W | GRADE 42 GRADE 50 ,GRADE 50T, GRADE 60 |

| API 2Y | GRADE 50, GRADE 60 |

| ASTM 240 | GRADE 310S, GRADE 310, GRADE 309, GRADE 309S, GRADE 316, GRADE 316L, GRADE 316Ti, GRADE 317, GRADE 317L,GRADE 321, GRADE 321H, GRADE 347, GRADE 347H, GRADE 304, GRADE 304L, GRADE 302, GRADE 301,GRADE 201, GRADE 202, GRADE 403, GRADE 405, GRADE 409, GRADE 409L, GRADE 410, GRADE 410S, GRADE 420, GRADE 430, GRADE 631, GRADE 904L, GRADE DUPLEX,ETC. |

| DUPLEX |

ASTM A240, GRADE S31803 |

| SUPER DUPLEX | ASTM A240 GRADE S32205, GRADE S32750, GRADE S32760 |

| High Strength Low Alloy (HSLA) Steel Plate | CSA G40.21, Grade 44W, Grade 50W, ASTM A709 Grade 36, Grade 50, Grade 50W, Grade 70W, A ASHTO M270 Gr50, 50W, A588 & A606 Steel Plates, A871-65 Steel Plates |

| A656 Steel Plates | A656 Gr 50, 60, 70, 80 |

| A573 Steel Plates | A573 Gr 58, 65, 70 |

| A283 Steel Plates | A283 Steel Plates |

| Quenched & Tempered Alloy Steel Plate | A514 Steel Plates Gr B, E, F, H, Q, S, 130ksi/890 MPa, TMCP 100 ksi Steel Plates, A710 Steel Plates |

| As Rolled Alloy Steel Plate | ASTM A829 & 4140 Steel Plates |

| Abrasion Resistant Steel Plate | AR235/AR Medium, AR400/400F, AR450/450F, AR500/500F, AR600 |

| PVQ Pressure Vessel Steel Plate | A516 Gr 55,60,65,70, TC128, A612, A537, A285 |

| Offshore & Marine Steel Plate | ABS Gr A, B, AH36, DH36, EH36, A 633 |

| Armor & Ballistic Steel Plate | A46100, A12560, A46177 |

| Low/High Non-Structural Steel Plate | A830-1045, C1020 |

| Caterpillar Spec Steel Plate | 1E0650,1E0357, 1E0860, 1E1021, 1E0742, 1E1259, 1E1247, 1E1242, 1E0577, 1E0170, 1E1839, 1E0653, 1E1006, 1E0065, 1E0682, 1E1863 |

| Offshore and Marine Steel Plate | |

| Boiler, Pressure Vessels and Chrome Moly Steels | BS 1501-161-430 A/B, BS 1501-224-490B LT50,BS 1501-223-490B LT50, BS 1501-225-490B LT50, BS EN 10207 SPH 265, BS EN 10028 P265 GH, BS EN 10028 P355 NL1,BS EN 100028 – 3 1993 , P460 NL1 |

| Alloy Plate | Alloy Plate – 4140 / 4340 / 8620 – ASTM A 829 |

| ASME SA387 and ASTM A387 Chrome Moly Plate | ASME SA / ASTM A387 Gr 11 Cl. 2, ASME SA / ASTM A387 Gr 22 Cl. 2, ASME SA / ASTM A387 Gr 5 Cl. 2, ASME SA / ASTM A387 Gr 9 Cl. 2 |

|

HIC Steel Plate |

ASME SA516 HIC & ASTM A516 HIC, CarElso HIC Premium+ |

Our Products are as below:

| HALF PIPE SLEEVE | LEAK REPAIR CLAMPS | GIRTH WELD SLEEVE |

| INSERT PIPE SLEEVE | SPLIT SLEEVE | PIPE LINE REPAIR SLEEVE |

| GALVANIZED WALL SLEEVE | TYPE B SLEEVE | PIPE LINE REPAIR SLEEVE WITH GROOVE |

| LEAK DEFECT REPAIR SLEEVE | WELD REPAIR ON SLEEVE | TYPE B SLEEVE WITH BACKING STRIP |

| PRE – STRESSED METALLIC SLEEVE | HALF REPAIR SLEEVE | SPLIT REPAIR SLEEVE |

| 360 DEGREE WRAP SLEEVE | TYPE A SLEEVE | HALF SPLIT SLEEVE |

| ARMADILLO SLEEVES | PRESTRESSED METALLIC SLEEVE | HALF SOLE SLEEVE |

| BOLT ON REPAIR CLAMPS | STEEL REPAIR SLEEVES | HALF WRAPE SLEEVE |

| SPLIT SLEEVE REPAIR CLAMP | HALF SOLE SEGMENTS | HALF REPAIR SLEEVE |

| FULL ENCIRCLEMENT STEEL SLEEVE | SPLIT REINFORCING SLEEVE | STEEL REPAIR SLEEVES |

| HALF REPAIR PIPE SLEEVE | WELD ON REPAIR SLEEVE | Bolted Repair Clamp |

| ENCAPSULATING TYPE LEAK CLAMP | REPAIR CLAMP | BOLT ON SPLIT SLEEVE |

| VENT PLUG TYPE LEAK CLAMP | BOLTED CLAMP | PIPE REPAIR CLAMP |

| SPLIT CLAMP | SPLIT SLEEVE CLAMP | EMERGENCY PIPELINE REPAIR CLAMP |

| PIPELINE LEAK REPAIR CLAMP | ELBOW REPAIR CLAMP | BOLTED PIPELINE LEAK REPAIR CLAMP |

| SPLIT SLEEVE REPAIR CLAMP | REPAIR SLEEVE CLAMP | SPLIT SLEEVE LEAK CLAMP |

| SPLIT SLEEVE SUBSEA PIPELINE REPAIR CLAMPS | PIPE MATE | NEEDLE CLAMP |

| SPLIT SLEEVE CLAMP | ELBOW AND TEE CLAMP | BOLTED REPAIR CLAMP |

| TYPE B SLEEVE | FULL ENCIRCLEMENT STEEL SLEEVE TYPE B | TYPE B SLEEVE WITHOUT BACKING STRIP GROOVE |

| MECHANICAL SLEEVE | SLEEVE TO CARRIER PIPE | PIPELINE REPAIR SLEEVE |

| MECHANICAL SLEEVE TYPE B | TYPE B SLEEVE WITH BACKING STRIP GROOVE |

Export Destinations of our Sleeves

|

MIDDLE EAST » Saudi Arabia |

AFRICA » Nigeria NORTH AMERICA » Usa |

EUROPE » Russia |

ASIA » India SOUTH AMERICA » Argentina |