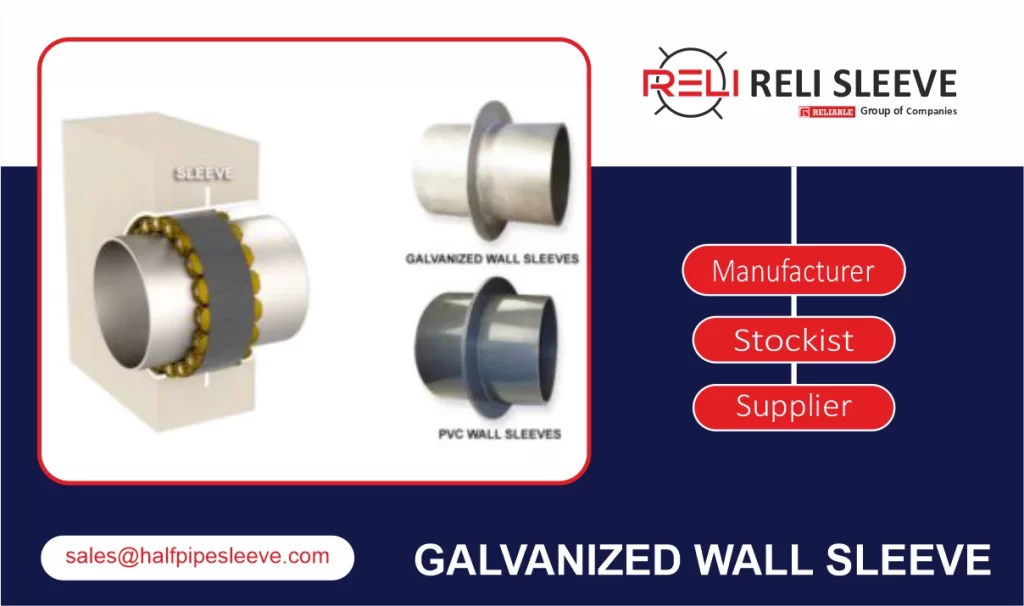

Galvanized steel wall sleeves are an option to create a hole penetration in a concrete wall. They are placed into the frame before pouring, and leave a clean hole. A water stop ring is provided. The Wall Sleeves have pipes and conduit running through them that can be sealed with the reli galvanized sleeve product. Reli galvanized sleeves provide a corrosion-resistant sealing surface for pipes penetrating floors, walls, foundation, or any concrete barrier. The sleeves, offered in galvanized steel, include a 2” water-stop to provide both stability and protection against moisture penetrating the wall. The steel is readily available from stock in 2” through 30” diameter sizes at 12” lengths. Custom lengths and sizes are available upon request. Galvanized steel wall sleeves suitable for concreting or bricking in. They are supplied in standard lengths of 400 mm and can be easily trimmed to the wall thickness on site. Galvanized steel wall sleeves are made of welded or seamless steel pipes. They are galvanized to protect them against corrosion. Other corrosion protection measures are available upon request (e.g. electrostatic powder coating). Click here for API 5L Pipe Sleeve.

Galvanized Steel Wall Sleeve are made of welded or seamless steel pipes or steel with a welded steel water stop, Galvanize epoxy coating. Other corrosion protection measures are also available upon request. The pipe wall sleeves are used to create a hole penetration in a concrete wall. They are Galvanized to make them corrosion-resistant. They are provided with a water stop ring. Our Galvanizes wall penetration sleeve provides corrosion-resistant sealing surface for pipes penetrating wall, floors, foundation or any concrete barriers. The steel pipe sleeves are used in gas applications, power plants, potable & water waste, oil platform, jet fuel transfer, refineries, general mechanical engineering, pipelines and chemical and industrial plants etc. These wall sleeves are designed to fit wall thickness as well as ductwork size and common pipe. To prevent the moisture from penetrating the wall and for better stability the galvanized wall sleeves are included with a 2” water-stop. They are available many sizes. The steels are available from 2” to 30” diameter size at 12’ length. You can also get them custom made with different length and size on request. The galvanized wall sleeves are more suitable for bricking and concreting. The standard length they are supplied is 400 mm. They can be easily trimmed to the wall thickness on site. Most of the time the wall damage is often caused by vibration of utility piping or pipe repair, but these problems can be avoided by using our wall sleeves. With our complete sealing system which includes wall sleeves with water stop and galvanized epoxy coating wall penetration seals. These products provide you with the necessary seal for your piping system. If you’re facing any sealing problems like a seals that’s not matched by the core drilled holes then our sleeve walls are the answer to your problem. Our sleeve walls are available in both carbon steel and pvc standard wall sleeves. They are both available in 12” length with 2” water stop with the standard diameters from 2”to “24. They are stocked and ready for shipment. You can also get them custom made on special request. Blast and gas protection shelter walls are provided with wall sleeves for incoming and outgoing utilities to attain protection level in terms of gas tightness, durability and pressure. Galvanized steel wall sleeves are the best method to create a perfect hole in the wall when penetrating copper, cast iron, steel or plastic pipes through ceilings, walls or floors. Galvanized steel wall sleeves are also the best option that provides best condition for a seal to work.

BENEFITS OF GALVANIZED STEEL WALL SLEEVES

Our complete sealing system includes Galvanized epoxy coating Wall Penetration Seals and Wall Sleeves with water stops. Working together, these products will provide you with the necessary seal for your piping system. Read More Wall damage, often caused by vibration of utility piping or pipe repair, can easily be avoided using RELI’s wall sleeves. Providing a seal that cannot be matched by core drilled holes, our wall sleeves are the answer to your sealing problems. RELI’s wall sleeves have been specifically designed to pair with RELI’s wall sleeves Wall Penetration Seals for a leak resistant sealing system. RELI WALL SLEEVE offers both Carbon Steel and PVC standard wall sleeves in 12” lengths with 2” water stops. Standard diameters, 2” through 24”, are stocked and ready for immediate shipment. Custom diameters and lengths are also available upon request. RELI WALL SLEEVE are available in stainless steel and carbon steel with our new Infinity wall sleeve manufactured in HDPE. The standard length is 12”; longer and shorter lengths are available. Steel wall sleeves are available in sizes from 2” to 120” diameter. When penetrating steel, cast iron, copper or plastic pipes through walls, ceilings or floors, RELI GALVANIZED wall sleeves are the best method to create a perfect hole inside the wall and provide best conditions for a seal to work. Wherever the modular seal is used to seal the annular space between the carrier pipe and the wall penetration, it makes sense to use RELI-SLEEVE wall sleeve. RELI GALVANIZED wall sleeves are made of welded or seamless steel pipes. They are galvanized to protect them against corrosion. Other corrosion protection measures are available upon request (e.g. electrostatic powder coating). The standard RELI-SLEEVE is supplied with a welded-on anchor flange. It acts as an annular water-stop plate which provides a 100% seal around the outer diameter and also serves as a wall anchor.

GALVANIZED WALL PENETRATION SLEVEES is a Part of your watertight sleeve seal system

Galvanized or PVC Corrosion resistant 2” anchor collar/water-sto 2” through 108” diameter

Material

- API 5L GRADE B, API 5L GRADE X42, API 5L GRADE X46, API 5L GRADE X52, API 5L GRADE X56, API 5L GRADE X 60, API 5L GRADE X 65, API 5L GRADE X70 – PSL 1 – PSL2 (minimum yield 245000 / 52000 / 60000 / 65000 / 70000)

- ASTM A36 (structural; minimum yield 36,000 psi)

- ASTM A572 GRADE 42, ASTM A572 GRADE 50, ASTM A572 GRADE 55, ASTM A572 GRADE 60, ASTM A572 GRADE 65 (structural; minimum yield 29,000 psi)

- ASTM A516 GRADE 55, ASTM A516 GRADE 60, ASTM A516 GRADE 65, ASTM A516 GRADE 70 (pressure vessel; minimum yield 38,000 psi)

- ASTM A537 Class I, ASTM A537 Class 2, ASTM A537 Class 3 (pressure vessel; minimum yield 50,000 psi)

- EN 10025 – GRADE S235, EN 10025 – GRADE S275, EN 10025 – GRADE S355, EN 10025 – GRADE S450 , EN 10025 – GRADE S185, EN 10025 – GRADE S235JR , EN 10025 – GRADE S235JRG1, EN 10025 – GRADE S235JRG2, EN 10025 – GRADE S235JO , EN 10025 – GRADE S235J2G3 , EN 10025 – GRADE S234J2G4, EN 10025 – GRADE S275JR, EN 10025 – GRADE S275JO , EN 10025 – GRADE S275J2G3, EN 10025 – GRADE S275J2G4, EN 10025 – GRADE S355JR , EN 10025 – GRADE S355JO, EN 10025 – GRADE S355J2G3 , EN 10025 – GRADE S355J2G4 , EN 10025 – GRADE S355K2G3, EN 10025 – GRADE S355K2G4

- ASTM A515- GRADE 60, ASTM A515- GRADE 65, ASTM A515- GRADE 70

- EN 10025 – COMPLETE RANGE – EN 10025 – Grade S235JR, EN 10025 – Grade S235 JO, EN 10025 – Grade S235 J2, EN 10025 – Grade S235 K2, EN 10025 – Grade S275 JR, EN 10025 – Grade S275 JO , EN 10025 – Grade S275 J2 , EN 10025 – Grade S355 JR, EN 10025 – Grade S355 JO, EN 10025 – Grade S355 J2, EN 10025 – Grade S420 JR, EN 10025 – Grade S420 JO, EN 10025 – Grade S420 J2, EN 10025 – Grade S690 JR, EN 10025 – Grade S690 JO, EN 10025 – Grade S690 J2, EN 10025 – Grade S890 JR, EN 10025 – Grade S890 JO , EN 10025 – Grade S890 J2, EN 10025 – Grade S450J0

- EN 10028- GRADE p355NL1, EN 10028 – GRADE p355NL2, EN 10028 – GRADE P275NH, EN 10028 – GRADE P460NL1, EN 10028 – GRADE P460NL2, EN 10028 – GRADE p460NH , EN 10028 – GRADE P355NL1, EN 10028 – GRADE P355NL2, EN 10028 – GRADE P355NH, EN 10028 – GRADE P235GH, EN 10028 – GRADE P265GH, EN 10028 – GRADE P295GH, EN 10028 – GRADE P355GH, EN 10028 – GRADE P235GH, EN 10028 – GRADE P265GH, EN 10028 – GRADE P295GH , EN 10028 – GRADE P355GH, EN 10028 – GRADE 360 , EN 10028 – GRADE 400, EN 10028 – GRADE 430

- ASTM A238- GRADE A, ASTM A238- GRADE B, ASTM A238- GRADE C, ASTM A238- GRADE D

- ASTM A285-GRADE A, ASTM A285-GRADE B, ASTM A285- GRADE C

- API 2H- GRADE 42 , API 2H- GRADE 50

- API 2W- GRADE -42 API 2W- GRADE E 50 AND 50T , API 2W- GRADE 60

- API 2Y- GRADE -50, API 2Y- GRADE 60

- ASTM 240-GRADE 310S, ASTM 240 -GRADE 310, ASTM 240-GRADE 309, ASTM 240-GRADE 309S, ASTM 240-GRADE 316, ASTM 240-GRADE 316L, ASTM 240- GRADE 316Ti, ASTM 240- GRADE 317, ASTM 240-GRADE 317L, ASTM 240-GRADE 321, ASTM 240-GRADE 321H, ASTM 240-GRADE 347, ASTM 240- GRADE 347H, ASTM 240-GRADE 304, ASTM 240-GRADE 304L, ASTM 240-GRADE 302, ASTM 240- GRADE 301, ASTM 240-GRADE 201, ASTM 240-GRADE 202, ASTM 240-GRADE 403, ASTM 240-GRADE 405, ASTM 240- GRADE 409, ASTM 240- GRADE 409L, ASTM 240- GRADE 410, ASTM 240-GRADE 410S, ASTM 240-GRADE 420, ASTM 240- GRADE 430, ASTM 240-GRADE 631, ASTM 240-GRADE 904L, ASTM 240-GRADE DUPLEX,ETC.

- DUPLEX-ASTM A2205 GRADE 2205, ASTM A2205 GRADE S31803

- SUPER DUPLEX- ASTM A2205 , ASTM A2205 GRADE S 32750, ASTM A2205 GRADE S32760

OUR CUSTOMERS

Petroleum companies such as Exxon-Mobil, Shell, & Philips Large engineering constructors Bechtel & Fluor Auto makers GM, Ford, Chrysler, & Toyota Chemical giants such as BASF, 3M, & Air Products Steel companies such as Nucor Countless other industrial, water & waste, and power customers.

Our Products are as below:

| HALF PIPE SLEEVE | LEAK REPAIR CLAMPS | GIRTH WELD SLEEVE |

| INSERT PIPE SLEEVE | SPLIT SLEEVE | PIPE LINE REPAIR SLEEVE |

| GALVANIZED WALL SLEEVE | TYPE B SLEEVE | PIPE LINE REPAIR SLEEVE WITH GROOVE |

| LEAK DEFECT REPAIR SLEEVE | WELD REPAIR ON SLEEVE | TYPE B SLEEVE WITH BACKING STRIP |

| PRE – STRESSED METALLIC SLEEVE | HALF REPAIR SLEEVE | SPLIT REPAIR SLEEVE |

| 360 DEGREE WRAP SLEEVE | TYPE A SLEEVE | HALF SPLIT SLEEVE |

| ARMADILLO SLEEVES | PRESTRESSED METALLIC SLEEVE | HALF SOLE SLEEVE |

| BOLT ON REPAIR CLAMPS | STEEL REPAIR SLEEVES | HALF WRAPE SLEEVE |

| SPLIT SLEEVE REPAIR CLAMP | HALF SOLE SEGMENTS | HALF REPAIR SLEEVE |

| FULL ENCIRCLEMENT STEEL SLEEVE | SPLIT REINFORCING SLEEVE | STEEL REPAIR SLEEVES |

| HALF REPAIR PIPE SLEEVE | WELD ON REPAIR SLEEVE | Bolted Repair Clamp |

| ENCAPSULATING TYPE LEAK CLAMP | REPAIR CLAMP | BOLT ON SPLIT SLEEVE |

| VENT PLUG TYPE LEAK CLAMP | BOLTED CLAMP | PIPE REPAIR CLAMP |

| SPLIT CLAMP | SPLIT SLEEVE CLAMP | EMERGENCY PIPELINE REPAIR CLAMP |

| PIPELINE LEAK REPAIR CLAMP | ELBOW REPAIR CLAMP | BOLTED PIPELINE LEAK REPAIR CLAMP |

| SPLIT SLEEVE REPAIR CLAMP | REPAIR SLEEVE CLAMP | SPLIT SLEEVE LEAK CLAMP |

| SPLIT SLEEVE SUBSEA PIPELINE REPAIR CLAMPS | PIPE MATE | NEEDLE CLAMP |

| SPLIT SLEEVE CLAMP | ELBOW AND TEE CLAMP | BOLTED REPAIR CLAMP |

| TYPE B SLEEVE | FULL ENCIRCLEMENT STEEL SLEEVE TYPE B | TYPE B SLEEVE WITHOUT BACKING STRIP GROOVE |

| MECHANICAL SLEEVE | SLEEVE TO CARRIER PIPE | PIPELINE REPAIR SLEEVE |

| MECHANICAL SLEEVE TYPE B | TYPE B SLEEVE WITH BACKING STRIP GROOVE |

Export Destinations of our Sleeves

MIDDLE EAST » Saudi Arabia | AFRICA » Nigeria NORTH AMERICA » Usa | EUROPE » Russia | ASIA » India SOUTH AMERICA » Argentina |