Split Tee Clamp

Split Tee Clamp Repair Solutions

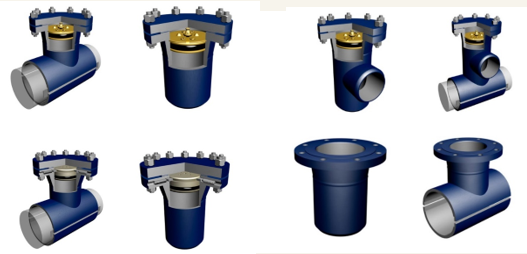

Split Tee Clamp repair solutions offer a quick, efficient, and reliable way to fix pipeline leaks without halting operations. To begin with, they serve as a cost-effective alternative to welding. Moreover, they reduce downtime, helping maintain uninterrupted service. Thanks to their design, Split Tee Clamps suit various pipe sizes and materials, making them highly versatile.

In addition, they meet strict industry standards and perform well under high-pressure conditions. Their simple installation lets in-house teams complete repairs safely and swiftly. As a result, sectors like oil, gas, and water utilities benefit from immediate and long-term solutions. All in all, Split Tee Clamps combine strength, safety, and adaptability, making them a smart choice for modern pipeline maintenance.

Features

Split Tee Clamp offers a wide range of features that make it highly efficient and reliable. To begin with, it allows pipeline repairs without any shutdown, ensuring continuous operation. Moreover, it provides a cost-effective alternative to welding, which helps reduce maintenance expenses. In addition, the clamp fits various pipe sizes and materials, enhancing its versatility. Not only that, but it also meets strict industry standards, making it ideal for high-pressure systems. Furthermore, the design ensures easy installation, so in-house teams can carry out repairs quickly. As a result, downtime is minimized, and productivity remains intact. Besides this, the Split Tee Clamp delivers long-term durability, even in harsh environments. Ultimately, it combines strength, safety, flexibility, and convenience—making it a smart choice for modern pipeline repair.

Material Specification

Pipe Sizes | 1″ & Above |

Split Body Shell | SA / ASTM A 516 Gr. 70 ASTM A 106 GR A, B, C Seamless Pipe ASTM A516 Gr. 70 Steel Plate API 5L Gr B, X42, X46, X52, X56, X60, X65, X70 ASTM A36 ASTM A572 Gr42, Gr50, Gr55, Gr60, Gr65 ASTM A516 Gr55, Gr60, Gr65, Gr70 ASTM A537 Class 1, Class 2, Class 3 EN 10025 ASTM A216 WCC ASTM A352 LCC ASTM A216 WCB |

Body Flange (Stiffner) | ASTM A350 LF2 / ASME || SA350 LF2 ASTM A105 / ASME || SA105 |

Stud & Nut | ASTM A 193 Gr. B7, with A194 Gr 2H. ASTM A 194 Gr2.2H, 2HM, 4, 7, 7M, 8, 8M ASTM A307 Gr A, B, C ASTM A320 Gr L7, L43 ASTM A325 Gr Type 1, Type 2, Type 3 Any other as per client requirement. Coating: Yellow Epoxy Polyamide, Standard or Marine Epoxy Galvanized, PTFE, Xylan Coated or any other. |

Seals / Gaskets | NBR temperature range is from -20°C to +80°C Viton temperature range is from -20°C to +200°C Silicone, Kevlar, Hycar HNBR temperature range is from -20°C to +150°C Any other as per client requirement |

Vent Plug | SA / ASTM A 105 |

Lifting Plug | SA / ASTM A 516 Gr. 70 |

Sacrifical Anode | Zinc Alloy |

Hinges Assembly | SA / ASTM A516 Gr. 70 SA / ASTM A-325 ASTM A106 Gr A, B, C, Seamless Pipes ASTM A572 Gr42, Gr50, Gr55, Gr60, Gr65 ASTM A516 Gr55, Gr60, Gr65 ASTM A36 ASTM A537 Class 1, Class 2, Class 3 EN 10025 – S235, S275, S355, S540 ASTM A 193 Gr. B7, with A194 Gr 2H Nuts. ASTM A 194 Gr2.2H, 2HM, 4, 7, 7M, 8, 8M ASTM A307 Gr A, B, C ASTM A320 Gr L7, L43 ASTM A325 Gr Type 1,Type 2,Type 3 |

Applicable International Standards

The design, engineering, and supply of the two fire tubes shall, wherever applicable and unless otherwise specified, conform to relevant standards such as API, ASTM, ANSI, ASME, or other recognized international equivalents. Furthermore, all applicable global standards and best practices will be followed throughout the process. Importantly, the latest versions of these standards will be used, thereby ensuring up-to-date compliance and technical accuracy at every stage.

API RP 1160 API 6H/ API 6X/ API 5L | Managing System Integrity of Hydrocarbon Liquid Pipelines |

ASME B31.3, ASME B31.4, ASME B31.8 | Pipeline Transportation System for Liquids |

ASME Section IX | Specification for Welding and Brazing Qualifications |

ASME Section V | Non-Destructive Examination |

ASME Section II Part C | Specification for Welding Rods, Electrodes and Filler Materials |

ASME Section VIII, Div 1 | Rules for Construction of Pressure vessels |

ASTM E 94 | Standard guide for Radiographic examinations |

ASTM E709 | Standard guide for Magnetic Particle examination |

ASTM E1003 | Standard test method for Hydrostatic Leak testing |

Testing & Certifications

– Non-destructive testing (NDT)

– 100% magnetic particle inspection (MPI) for stiffener to shell weld (fillet)

– 100% ultrasonic testing of vent plug welds

– 100% MPI fo hinge welds

– Hydro Test as per ASME Secion VIII Div. 1 clause UG-99 Dimensional & Visual

– Hardness

– Load Testing of Hook & Hinge

– Painting Inspection